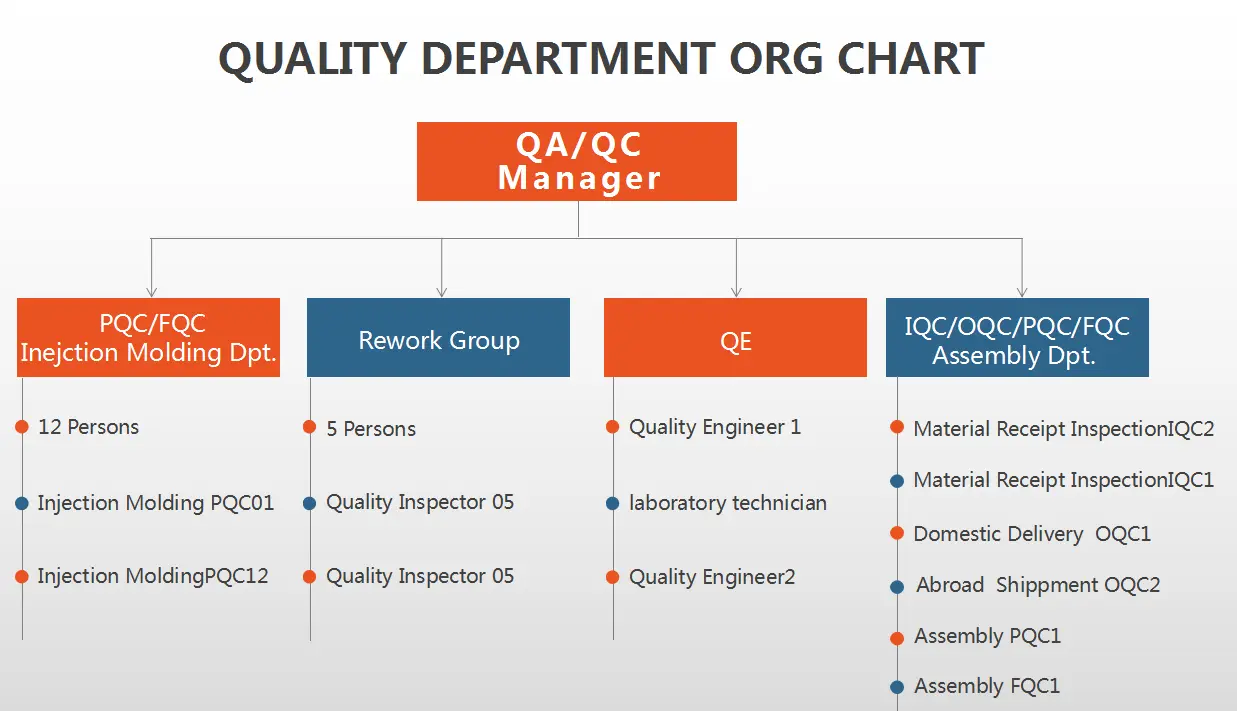

Reasonable organization chart of quality department can efficiently control the production process, and strictly operate according to Standard Operation Procedure(SOP) to massively avoid the possible quality issue.

1. Critical Defects (CR)

There is a danger to personal safety or the presence of defects that are hazardous to personal health. Such as leakage of electricity, water, plastic toxic, etc.

2. Major Defects (MA)

The loss of the main function of the product, will affect the service life, will affect the speed of assembly or serious appearance of bad directly affect the sale of the product. Such as lack of plastic, deformation, wrong size, etc.

3. Minor Defects (MI)

Minor appearance defects, will not directly affect the sales of the product. That is, defects other than CR, MA. Such as different color spots, scratches, air marks, shrinkage, etc.

1. Pest Control Trainning

2. Quality Standards Training

3. Customers Complaint Training

4. Health and Technical Training