Customer requirements:

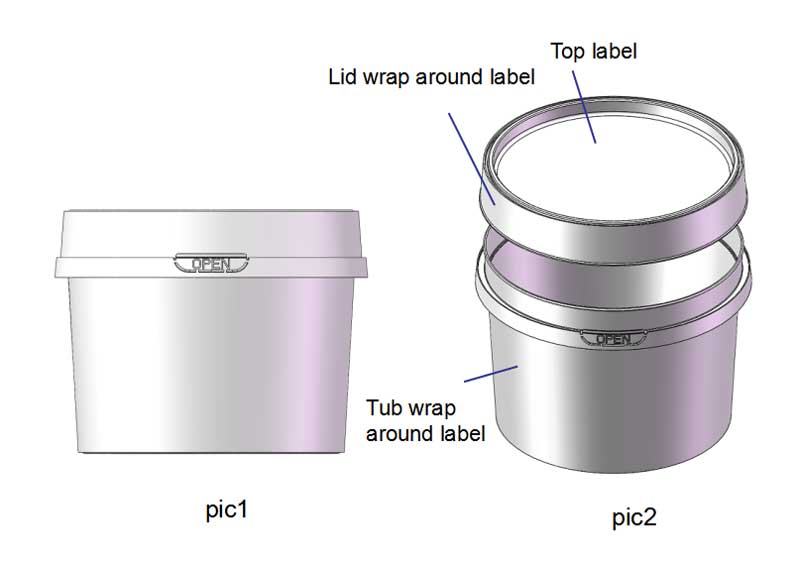

This is a classic ice cream bucket for Nestle. The original product is made by paper. There are patterns on the top and side of the lid. When the customer upgrades the paper to PP cup and lid, Customer requests to keep the appearance as consistent as the original paper cup as much as possible. That is, For lid both the top and side of the lid should be with IML.

For this plastic closure, the diameter is large and the height is small, which means the side lable should be very thin and long, the size is L370*W18, which is extremely difficult to apply on.

After technical research by our mold design and making department and automation department, Honokage finally successfully realized the mass production of this project. Not only for the IML cups production process of attaching two labels to the lid, but also 1. introduced ultra-low temperature quick freezing at -48 ℃, The resin we are using is for long-term and low-temperature storage 2. The production is with fully automated visual detection system, and automatic stacking and automatic packing system.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية हिंदी

हिंदी