IML (In-Mold Labeling) and injection molding is a manufacturing process that has developed rapidly in the food packaging industry in recent years. The principle is to put the printed PP film label into the mold cavity before injection molding. The label flim is melted with the product.

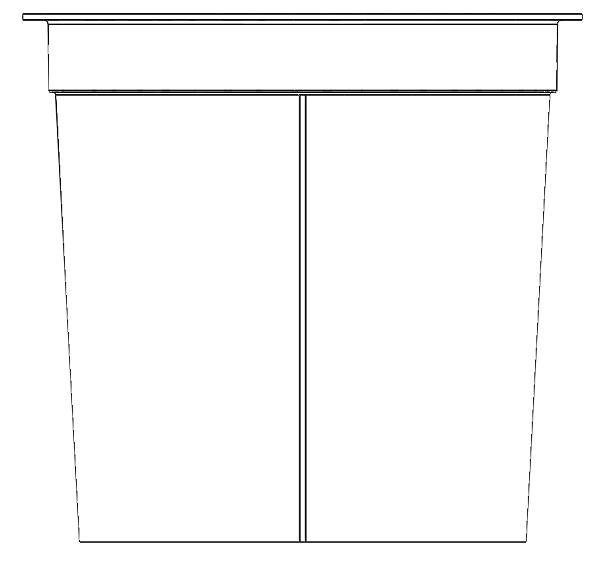

In-Mold Labeling thin-wall containers will have the joint seam of the label, and the common seam of the label in the food packaging industry is straight, as shown in below picture 1, when the container is thicker wall thickness or non-transparent PP material, The strength of the product has no effect; but when the container wall thickness is thin and made by high transparent PP material, when it is dropped and squeezed, it is easy to crack at the label joint position.

The reasons are as follows: 1. The high transparent PP material is relatively brittle. 2. Since the label itself has a certain thickness, there will be stress concentration at the joint position. The container will crack along the seam.

Existing solutions in the industry ignore the important influencing factor of the shape of the label seam, and only use thicker container walls (this will increase the material, increase the injection cycle time, and increase the cost) or use other tougher PP Material (this greatly reduces the transparency of the thin wall capacity, so that the product cannot meet the high-transparency appearance required by customers).

Picture1

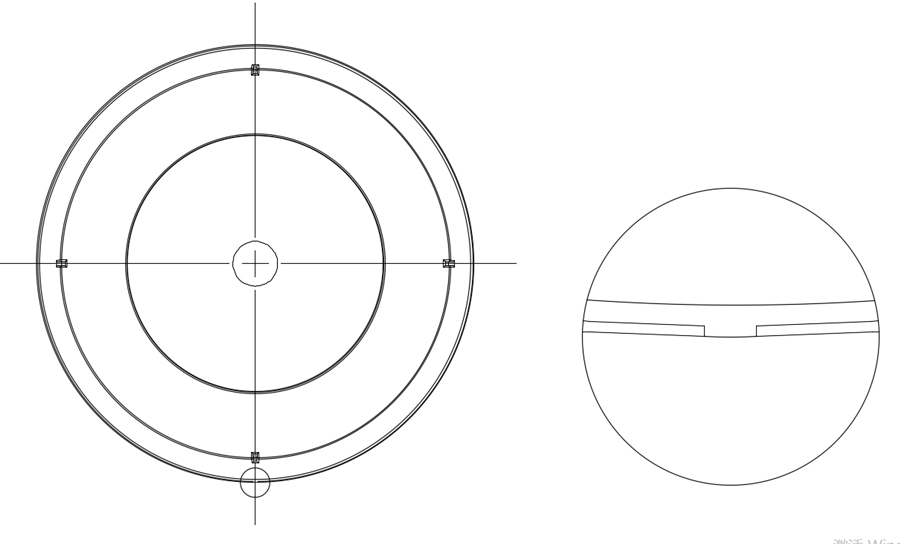

Picture2

Solution Description of IML Technology

The research purpose of this project is to provide a seam structure for In-Mold Labels for high transparent thin wall containers that can avoid container crack due to stress concentration when subjected to external force.

The seam structure of the In Mold Label of the high-transparent thin wall container, the in-mold label is melted to the outer surface of the container through the in-mold labeling process, wherein the In Mold Label is made of PP material, and when the two ends of the in-mold label are butted together, The seam formed is a curve, and the height from the top of the arc to the bottom of the arc is greater than 4 times the width of the seam.

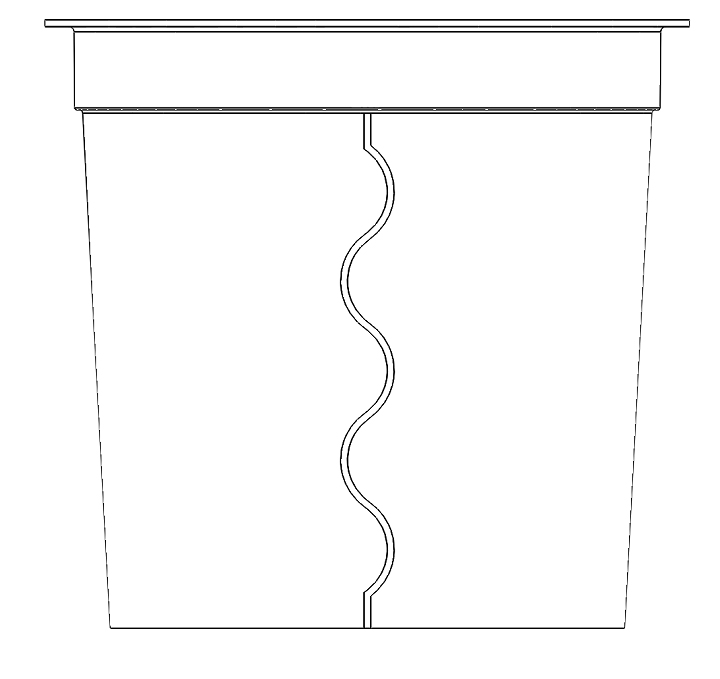

As shown in picture 3, when the two ends of the in-mold label are butted together, the seam formed is a wavy line.

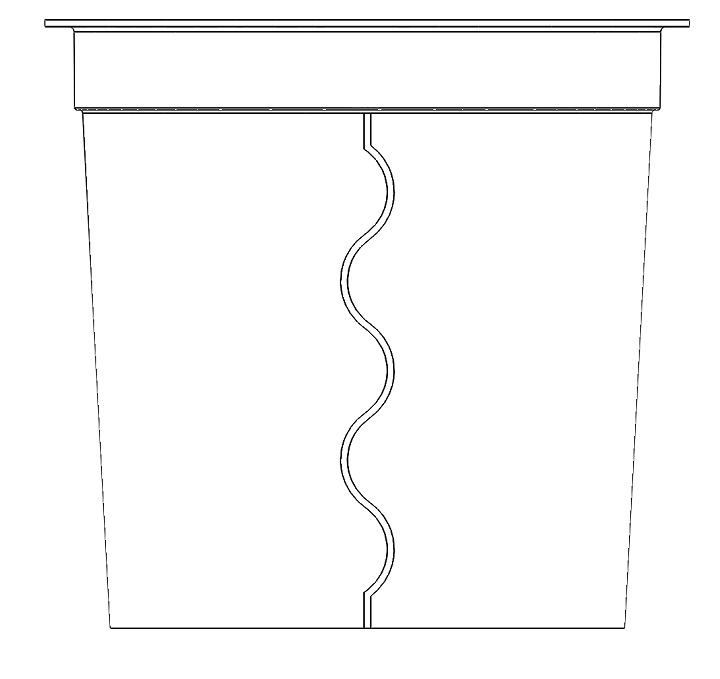

As shown in picture 4, when the two ends of the in-mold label are butted together, the seam "S" shape is formed.

After the above scheme is adopted, the seam that was originally parallel to the plastic flow direction during injection molding is curved, so that the stress concentration position caused by the seam is staggered from the plastic flow direction, so that the stress concentration is dispersed, and the stress concentration is avoided when the container is subjected to external force. and rupture.

According to the reason of product rupture, this solution proposes a simple and effective solution, which not only avoids the increase of cost, but also maintains the high transparent of the product.

Picture3

Picture4

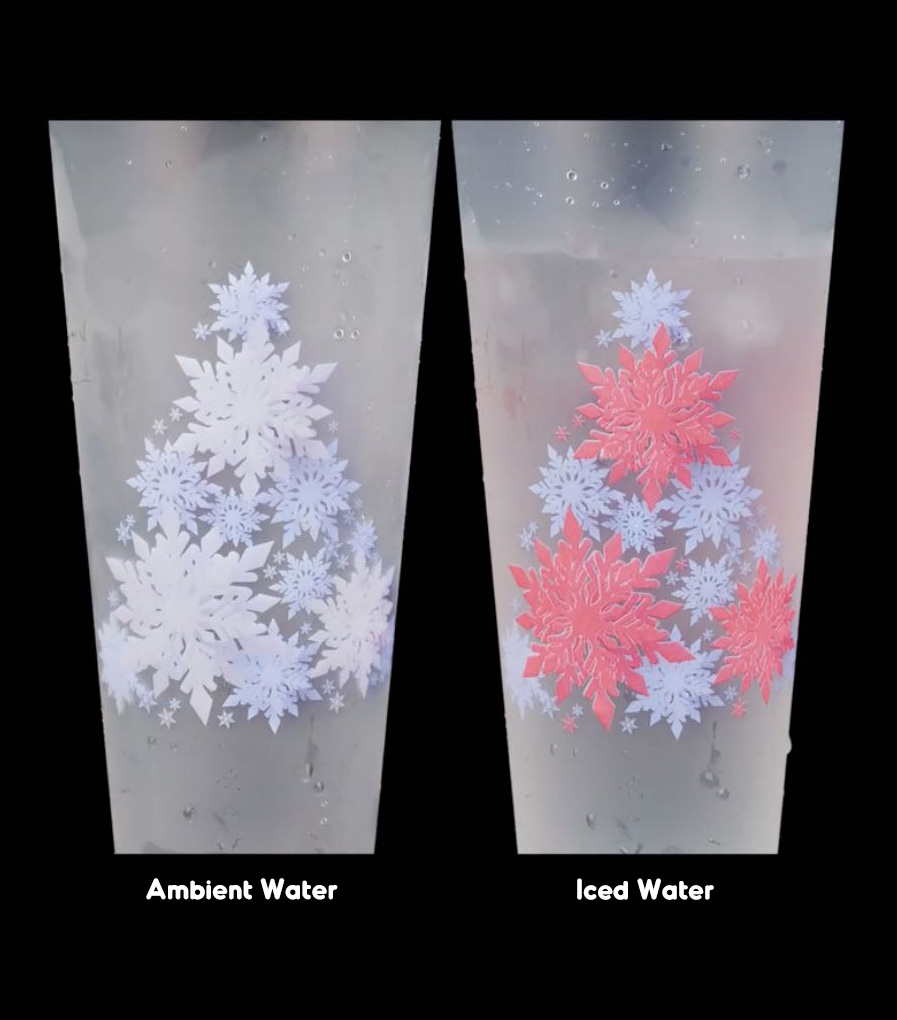

Temperature changeable cup is a kind of In-Mold labeling with color change effect and plastic processing molding. Cold change temperature during 20-5℃ gradually change, In-Mold Labeling features a color change printing layer for the temperature-sensitive color change printing layer or optical color change printing layer, temperature-sensitive color change printing layer is made by temperature-sensitive color change ink printed on the transparent protective layer of the pattern or text.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية हिंदी

हिंदी