Honokage has professional R&D and mold design team, which enables Honokage to provide product design solutions and provide moldflow analysis with faster response than others when receiving customer requests. Honokage's consultant of Tooling Design was Tupperware's Director of Tooling Design for 25 years.

Honokage is able to integrate all aspects of resources to be more flexible and efficient in smart manufacturing. It includes the integration of resources such as: in-mold labelling technology Seminars and production, procurement and commissioning of imported German equipment and automatic labelling systems, mold creation, automated inspection systems, food safety testing.

Upon receiving a technical problem from a customer, Honokage will first simulate the problem point, identify the cause, and provide an improvement plan within 48 hours, or communicating with customer via video about details if necessary, or sending a technician to provide on-site support.

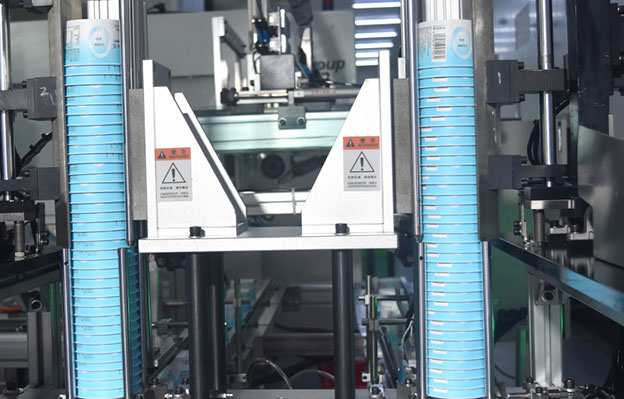

Honokage introduced in fully automatic system, including German imported high-speed injection molding machine, automatic labeling system, automatic inspection system, automatic stacking system and automatic packaging system to ensure quality safety and high efficiency production.